Sial Pahid Parsian Company, with 4 years of experience in the field of design and production of all types of repair clamps and branch valves for the water, gas and petrochemical industries, is ready to provide services to our dear compatriots.

For more information, you can contact the following numbers.

Managed by Mrs. Heydari

Products

Single jaw repair clamp

Double jaw repair clamp

Triple jaw repair clamp

four-jawed repair clamp

Flanged manifold

Bushni splitter

All parts of the repair clamp are made of stainless steel AISI 316 or AISI 304

The rubber seal used is EPDM, SBR, NBR.

Welding of all metal parts is done with argon welding under argon shielding gas

All nuts and washers are made with stainless steel material AISI316-AISI304

All flanges are designed to withstand working pressure PN1-PN16-10. All flanges body and repair clamp derivatives are made of stainless steel AISI304 or AISI316.

Tehran

🟧Kurdistan water and sewage

🟧Semnan water and sewage

🟧Ahwaz water and sewage

🟧 Tabriz water and sewage

🟧Khorasan water and sewage

🟧Ardabil water and sewage

🟧water and sewage engineering of the country

🟧Amlesh water and sewage

🟧Yasukand water and sewage

🟧Arsanjan water and sewage

🟧Damghan water and sewage

🟧Yazd water and sewage

🟧water and sewage of Khuzestan

🟧Lorestan water and sewage

🟧Shiraz water and sewage

🟧Bandar Abbas water and sewage

🟧Kish water and sewage

🟧water and sewage of Sistan and Baluchistan

🟧Abhar water and sewage

🟧water and sewage of East Azerbaijan

🟧Water and sewage of West Azerbaijan

🟧 Dezful water and sewage

🟧Nishabur water and sewage

🟧Zanjan water and sewage

🟧pipe fittings stores

🟧polyethylene stores

🟧 water and sewage supply companies

🟧 trading companies

🟧 Petrochemical Company

🟧Exports to Iraq and Afghanistan

Watertight clamp

The watertight clamp is used for pipe breakage and bursting, and the length of the clamp is determined depending on the extent of pipe breakage. And depending on the size of the pipe, it is used as a single jaw, two jaws and three jaws.

Watertight clamps can be used for the following types of pipes:

1. Ductile iron pipes

2. Steel pipes

3. Steel pipes

4. Class a-b-c asbestos pipes

5. Poly PVC pipes

6. Polyethylene pipes

All parts of the repair clamp are made of AISI 304 or AISI 316 stainless steel.

The used sealing rubber is SBR, EPDM, NBR.

Welding of all metal parts is done with argon welding under argon protective gas.

All screws are produced by roll forming method and covered by Teflon.

All nuts and washers are made with AISI 304 or AISI 316 stainless steel material.

All flanges are designed to withstand working pressure PN10 - PN16.

Drilling of all flanges is according to DIN 2576 and DIN 2551 standards.

All flanges, body and derivatives of the repair clamp are made of stainless steel AISI 304 or AISI 316.

How to install the sealing clamp

1. We clean the surfaces completely with a brush and napkin.

2. We mark the place of installation of the clamp so that it is accurately placed.

3. We tighten the bolts and nuts, this is repeated depending on the number of clamp jaws.

The watertight clamp can be divided into three categories:

Single jaw from 50 to 250 mm in diameter

Two jaws from 200 to 800 mm in diameter

Three jaws from 700 to 2000 mm in diameter

Advantages of repair clamp

Easy to use and complete sealing

With EPDM gasket

High resistance at 10 bar working pressure

Unique design and versatile functionality

Made of non-toxic and harmless materials for humans

Exact dimensions and branch output if needed

Manufactured from the best UPVC material

Suitable for iron, polyethylene, polypropylene, cast iron, composite pipes

Used in agricultural industry, building facilities and urban water distribution network

Applications and important points of repair clamp

Repair clamp, which is also known by other names such as repair clamp, repair clamp, pipe clamp, repair clip, pressure clamp, strap repair and holding clamp, is widely used in various industries. Due to its easy installation and high performance, this tool is an ideal choice for quick repair of damaged pipes.

Uses of repair clamps:

1. Oil and gas industries: repair of oil and gas transmission pipes without the need to completely stop the process.

2. Water and sewage systems: preventing water leakage and waste in sewage distribution and collection networks.

3. Agriculture: repair of irrigation pipes and water transfer systems in fields and gardens.

4. Construction facilities: fixing leaks in hot and cold water pipes, heating and cooling systems.

5. Chemical and petrochemical industries: resistant to chemicals and suitable for repairing pipes containing corrosive fluids.

Splitter clamp

Category: Repair clamps

Tag: splitter repair clamp, single-jaw repair clamp, double-jaw repair clamp, three-jaw repair clamp

Splitter clamp

Category: Repair clamps

Tag: splitter repair clamp, single-jaw repair clamp, double-jaw repair clamp, three-jaw repair clamp

The branching clamps are produced in two models with umbilical (bushing) and flanged and are made of stainless steel, and are used for branching or changing the diameter of ductile iron, steel, steel, asbestos pipes in different classes, polymer and GRP pipes in the water, gas and petrochemical industries.

Specifications of the splitter clamp

All metal parts are made of stainless steel AISI 304 and AISI 316.

The used rubber is made of NBR, SBR, EPDM.

Welding of all metal parts is done by argon welding under argon protective gas.

All screws are produced by roll-forming method and covered by Teflon.

All nuts and washers are made of stainless steel AISI 304 or AISI 316.

Flanges are designed for PN10/16 working pressure.

The drilling of all flanges is based on DIN2576 and DIN2501 standards.

The flanges and the body and accessories of the manifolds are made of stainless steel AISI 304 or AISI 316.

autorenew

thumb_up

thumb_down

Ulbilized splitter clamp

The umbilical branching clamp is produced in branching sizes ½", ¾", 1", 1¼", 1½", 2", 3", 4".

2", 3", 4" clamps are made with two jaws. Also, when choosing a splitter, you should pay attention to the minimum length of the splitter body.

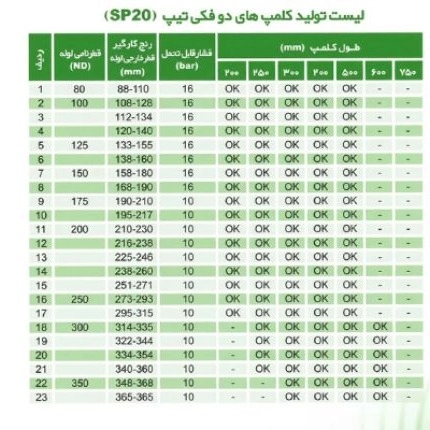

Minimum required length of the body, external diameter of the tube, umbilical size of the branch (mm) from the main to the outlet drop 👇

branch size main pipe outer diameter (mm) minimum body length (mm)

½" ≥44mm 150

¾" ≥50mm 150

1" ≥57mm 150

1¼" ≥67mm 150

1½" ≥70mm 200

2" ≥89mm 200

2½"* ≥109mm 200

3"* ≥128mm 300

4"* ≥158mm 400

Producible sizes of umbilical branching clamp

- Single-jaw umbilical branching clamps can be designed and produced for pipes with an external diameter of 44mm to 346mm and lengths of 200, 250, 300, 400, 500 and 600 mm.

- Two-jaw umbilical manifolds can be designed and produced for pipes with an external diameter of 109mm to 645mm and lengths of 200, 250, 300, 400, 500, 600, 750 and 1000 mm.

Operating pressure of umbilical branching clamp

- For pipe diameter 40 to 150, 16 bar tolerable pressure

- For pipe diameter 175 to 300, 10 bar tolerable pressure

Flanged branching clamp

Manufacturable sizes of flanged manifold clamp

- Single jaw flanged manifolds are designed and produced for pipes with a diameter of 87mm to 346mm and lengths of 200, 250, 300, 400, 500, 600, 750 and 1000 mm.

- Two-jaw flanged manifolds are designed and produced for pipes with a diameter of 109mm to 1200mm and lengths of 300, 400, 500, 600, 750, 800 and 1000 mm. Specifications of branch clamps flange - All flanges are made of 304 or 316 steel.

- The drilling of the flanges used in the manifolds is according to DIN2576 and DIN2501 standards.

- The flanges are designed and manufactured based on the standard for PN10 and PN16.

Working pressure of flanged branching clamp

- For pipe diameter 80 to 500 pressure can withstand 16 bar.

- For pipe diameter 600, pressure can withstand 10 bar.

The minimum body length of flanged manifolds is determined from the table below 👇

| ND branching flange (mm) | Minimum length of the splitter body (mm) |

|-------------------------|--------------------------------| 50 | 300 |

| 65 | 300 |

| 80 | 300 (400) |

| 100 | 400 |

| 125 | 400 |

| 150 | 400 |

| 200 | 500 |

| 250 | 600 |

| 300 | 750 |